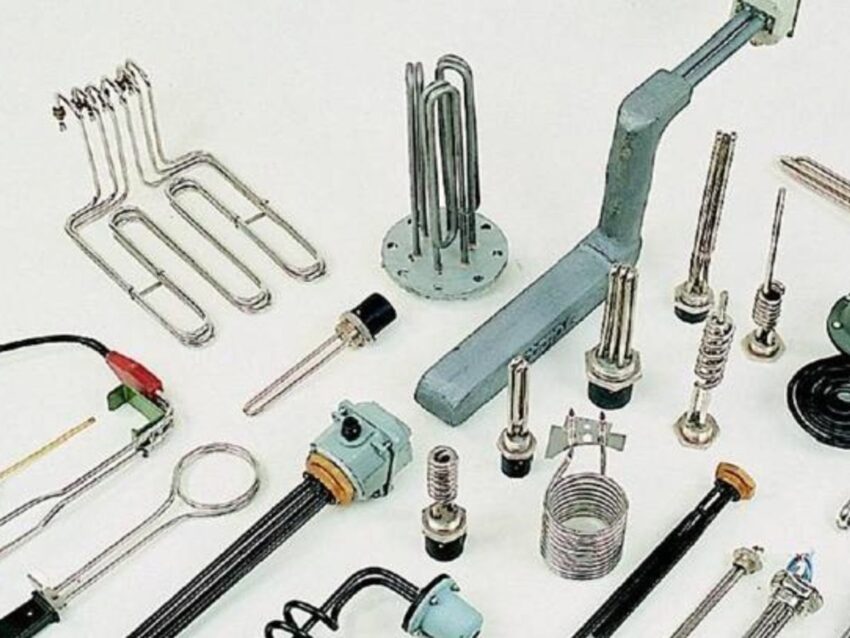

For manufacturers producing cartridge heaters and other industrial heating products, safety validation goes far beyond visual inspection. Through deliberate testing protocols, reliable performance becomes the baseline, not the goal.

Internal Wiring Integrity Checks Before Units Leave Production

Before any heater leaves the assembly floor, technicians examine internal wiring for continuity and insulation integrity. This step ensures wires have been routed correctly and are free from abrasion, kinks, or pressure points that could cause future failures. For cartridge heaters used in high-cycle operations, such checks prevent overheating due to internal shorts or wire fatigue.

During these inspections, specialized tools measure insulation resistance between conductors and the sheath. This confirms that each unit meets thermal and electrical safety thresholds defined by the application it’s intended for. In the case of custom industrial heaters, where configurations often vary, internal wiring validation becomes even more important due to the complexity of the design.

Grounding Paths Tested to Prevent Stray Current Discharge

Proper grounding can be the difference between safe operation and catastrophic failure. Testing the continuity of grounding paths ensures any fault current can be safely discharged without harming nearby components or operators. Industrial heating accessories that operate on high watt densities particularly benefit from this safeguard.

In practical terms, this means every metallic part that could potentially carry electrical charge is connected to a tested grounding path. This prevents stray current from traveling through external surfaces, which could otherwise shock personnel or damage surrounding machines. Manufacturers of industrial heaters in the USA implement this procedure as standard to maintain safety and regulatory compliance.

Surface Temperature Consistency Reviewed Across Operating Cycles

Even heating distribution is key to both performance and safety. Surface temperature readings are taken at various stages of the heating cycle to confirm the element heats uniformly. If any area runs significantly hotter than others, it can trigger breakdowns in insulation or surrounding materials.

Consistency also ensures predictable performance in applications such as mold heating or food processing, where thermal variation can lead to process defects. These checks not only protect the heater itself but also help extend the life of surrounding components. For manufacturers of industrial heating products, surface monitoring allows real-time adjustments before shipment.

Resistance Readings Measured to Catch Early Coil Faults

By measuring resistance values in each heating element, manufacturers can detect irregularities that signal internal coil damage or variation in material composition. Resistance readings help confirm that wattage aligns with the heater’s rated specifications, ensuring stable energy transfer. These measurements can also reveal cold spots or inconsistencies within the heating wire before the unit is ever powered up. It’s one of the earliest steps used to screen out defective elements from the production batch. For custom industrial heaters, where each unit may have different watt densities or geometry, precise resistance testing confirms that the unit will perform as engineered.

Component Spacing Examined to Reduce Arc and Short Risk

Spacing between internal components, including wires, terminals, and insulation layers, is carefully reviewed during production. This distance prevents electrical arcs and reduces the likelihood of shorts caused by vibration or thermal expansion. Cartridge heaters and similar compact devices require tight tolerances, which makes spacing inspection even more important.

Design teams use standard clearance guidelines based on voltage and application environment, and these are verified again during quality control. Spacing checks play a critical role in heater longevity and fire prevention. Even the smallest gap misalignment could compromise the performance or safety of the entire system under load.

Connection Terminals Evaluated for Fatigue Under Heat Stress

Connection points are frequently subjected to bending, torque, and high heat—conditions that lead to long-term fatigue if not properly addressed. Each terminal is tested for mechanical durability and thermal resistance to confirm it can endure repeated heating cycles without cracking or loosening.

High-grade materials like nickel-plated brass or stainless steel are often used in industrial heating accessories to enhance terminal reliability. Testing for expansion under heat load helps ensure stable connections for the entire life of the heater. This level of attention to terminal stress proves essential for heaters used in dynamic environments or exposed to constant vibration.

Batch Samples Pulled Regularly for Destructive Validation Testing

Destructive testing isn’t performed on every unit, but batch sampling provides vital insight into real-world performance. Selected units are subjected to extreme thermal, electrical, and mechanical conditions until failure. This process uncovers weak points in materials or design that might not show during standard testing.

These tests are especially important for new product lines or revisions to existing heater designs. By validating performance limits through destruction, manufacturers confirm the safety margin built into their industrial heating products. This testing method strengthens the long-term reliability of cartridge heaters used across industries like plastics, aerospace, and pharmaceuticals, where precision matters most.