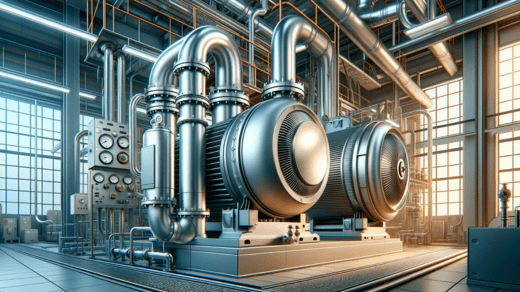

In the world of industrial equipment, efficiency and reliability are paramount. Side channel blowers and side channel vacuum pumps play a crucial role in various industries, ensuring the smooth operation of essential processes. In this article, we will delve into the intricacies of Side Channel Blowers and side channel vacuum pumps, exploring their functionality, applications, and benefits.

What Are Side Channel Blowers?

Side channel blowers, also known as regenerative blowers or ring compressors, are mechanical devices designed to generate air or gas flow by utilizing the principle of centrifugal compression. These compact and versatile machines are widely used in industrial applications that require high-pressure, low-flow air or gas movement.

How Do Side Channel Blowers Work?

Side channel blowers operate on a unique principle. They consist of an impeller with multiple small blades, which rotates within a carefully designed housing. As the impeller spins, it creates a series of air pockets or channels. These channels expand and contract, causing air to be drawn in and compressed before being expelled.

Applications of Side Channel Blowers

- Wastewater Treatment: Side channel blowers are crucial in aeration processes, promoting the growth of beneficial bacteria in wastewater treatment plants.

- Material Handling: They are used for conveying materials in various industries, such as plastics, food processing, and pharmaceuticals.

- Printing and Packaging: Side channel blowers aid in paper handling and ink drying in printing and packaging machines.

- Medical Equipment: These blowers provide the necessary air for medical devices like dental suction systems and respiratory machines.

Understanding Side Channel Vacuum Pumps

Side channel vacuum pumps, on the other hand, are closely related to side channel blowers but serve a different purpose. They are primarily designed to create a vacuum by removing air or gas from a closed space.

How Do Side Channel Vacuum Pumps Work?

Similar to side channel blowers, vacuum pumps utilize the regenerative principle. The impeller rotates within the housing, creating a vacuum within the channels. This vacuum then draws in the air or gas from the connected space, effectively evacuating it.

Applications of Side Channel Vacuum Pumps

- Vacuum Packaging: They are used to remove air from packaging containers, extending the shelf life of perishable goods.

- Woodworking: Side channel vacuum pumps hold workpieces in place on CNC routers and other woodworking machinery.

- Printing and Paper Handling: These pumps help with sheet separation and transport in printing and paper handling equipment.

- Environmental Testing: Side channel vacuum pumps are used in laboratories for creating vacuum environments required for experiments.

Benefits of Side Channel Blowers and Vacuum Pumps

Both side channel blowers and side channel vacuum pumps offer several advantages:

- Efficiency: They provide high flow rates and pressure differentials while consuming relatively low energy.

- Compact Design: These machines are space-saving and can be easily integrated into existing systems.

- Reliability: They are known for their durability and long operational life.

- Low Noise: Side channel blowers and vacuum pumps are quieter compared to other types of compressors.

- Oil-Free Operation: Many models are oil-free, making them suitable for sensitive applications.

In the world of industrial equipment, side channel blowers and side channel vacuum pump are indispensable tools. Their ability to generate high-pressure airflow and create vacuums makes them invaluable in a wide range of applications. These machines offer efficiency, reliability, and a compact design, making them the top choice for many industries.